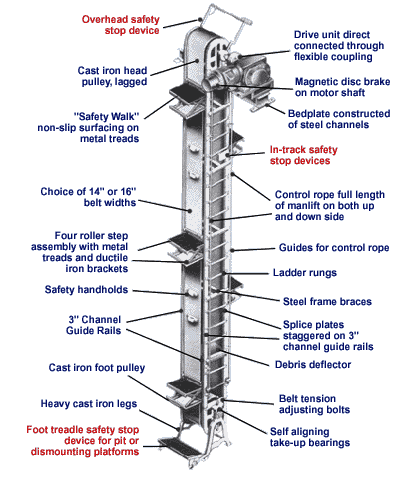

Belt Manlift

If your employees must travel vertically in the routine performance of their duties, the low-cost mechanical solution is the Humphrey Employees’ Belt Manlift. It provides reliable vertical transportation that saves time and energy. In contrast to conventional elevators, there is no waiting for a Humphrey Employees’ Belt Manlift. Its endless belt provides continuous transportation in both directions. An employee may step on or off at any floor without interrupting service for other employees using the belt manlift. One man can perform inspection or supervisory duties on a number of floors, rapidly, and without fatigue. Belt speed is 75 feet per minute for ease of getting on and off the moving steps.

Move your mouse over the red text to get a closer look…

Overheat Safety Stop Device

Dislodging of tubular bar activates limit switch to apply brake and stop manlift.

In-Track Safety Stop Device

Stops manlift if rider neglects to get off on the top floor. The device is tripped by the weight of the person on the step.

Foot Treadle Safety Stop Device

Stops manlift if rider steps on treadle board. Furnished when required.

The Humphrey Employees’ Belt Manlift can be installed in any new or existing multi-floor building. Initial cost, installation cost, and operating cost are all well below the costs of conventional elevators. A Humphrey Manlift takes only a fraction of the floor space. All models are heavy-duty construction, designed in accordance with the ASME A90.1 Safety Standard for Belt Manlifts.

Follow Us